Source: BAM

Additive manufacturing (or “3D printing”) holds great potential in modern production, especially for small- and medium-sized enterprises (SMEs). However, the complexity of the manufacturing process, with its numerous influencing parameters and the high level of component individuality, poses major challenges to existing quality assurance methods. SMEs in particular have very limited access to the costly common methods of nondestructive testing.

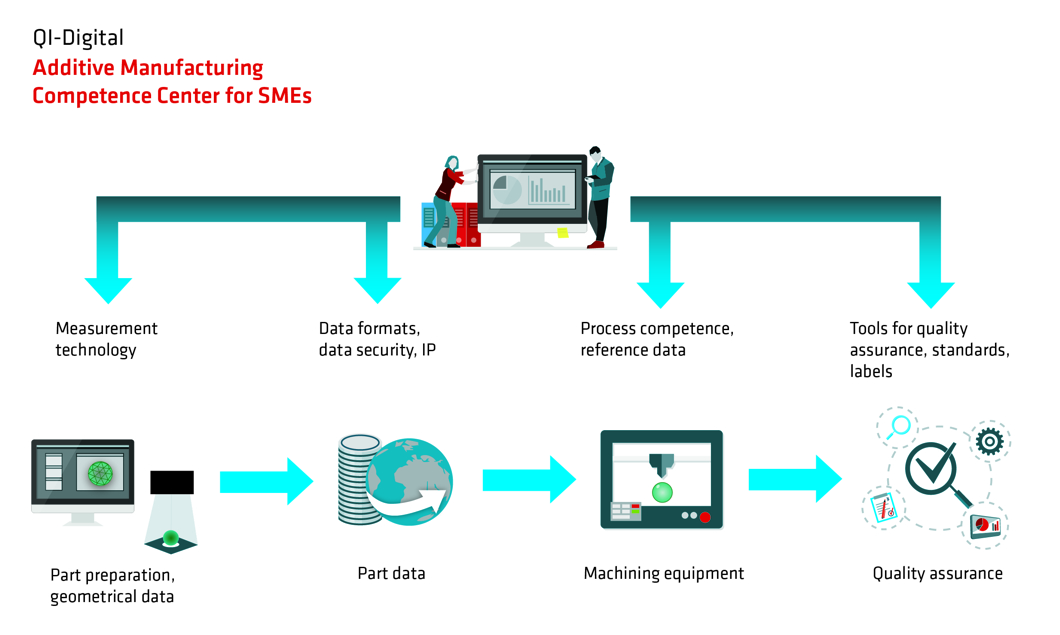

This is where the QI-Digital project comes in. New digitally supported solutions for additive manufacturing are to be developed together with users from SMEs, QI institutions, and research institutes. An open test environment in Berlin lies at the heart of the project. There, an industrial additive manufacturing chain is being mapped - from the determination of geometry to the use of computer tomography as a reference method - and joint research, development, testing, and trials are carried out.

Objectives

- Development of new process-integrated quality assurance measures (process monitoring)

- Further development and evaluation of nondestructive testing methods for downstream quality assurance

- New digital methods for the evaluation of process and measurement data

- Database systems for reference data of additive-processed materials

- Development of standards, guidelines for certification, and product labels